Menu

Type

Year

Grinding capacity

Grinding wheel

(Diameter / Width)

Weight

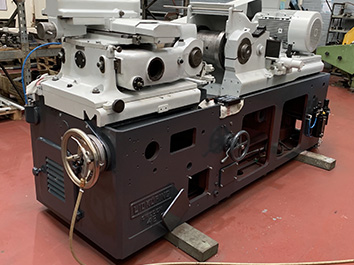

Hartex HT4/C

1982

max. Ø120 mm

600 x 250mm

Appr. 9,0t

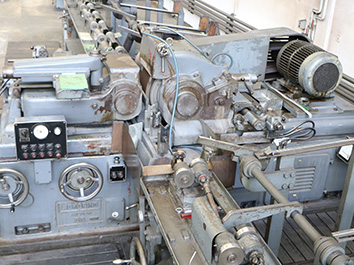

Lidkköping 2C

1966

max. Ø125 mm

500 x 250mm

Appr. 4,0t

Lidköping 4B/G

1962

max. Ø150 mm

508 x 254mm

Appr. 6,5t

Lidköping 5B

1961

max. Ø330 mm

660 x 254mm

Appr. 11,0t

Lidköping 46/G

1982

max. Ø240 mm

508 x 610mm

Appr. 8,5t

Lidköping 630

1996

max. Ø150 mm

610 x 300mm

Appr. 9,5t

Cincinnati 3-500

1978

max. Ø150 mm

600 x 510mm

Appr. 9,0t

Cincinnati 3-300

1976

max. Ø120 mm

600 x 250mm

Appr. 9,0t

Estarta 327

1987

max. Ø120 mm

600 x 500mm

Appr. 14,0t

Cincinnati 20M

Bordier FOP

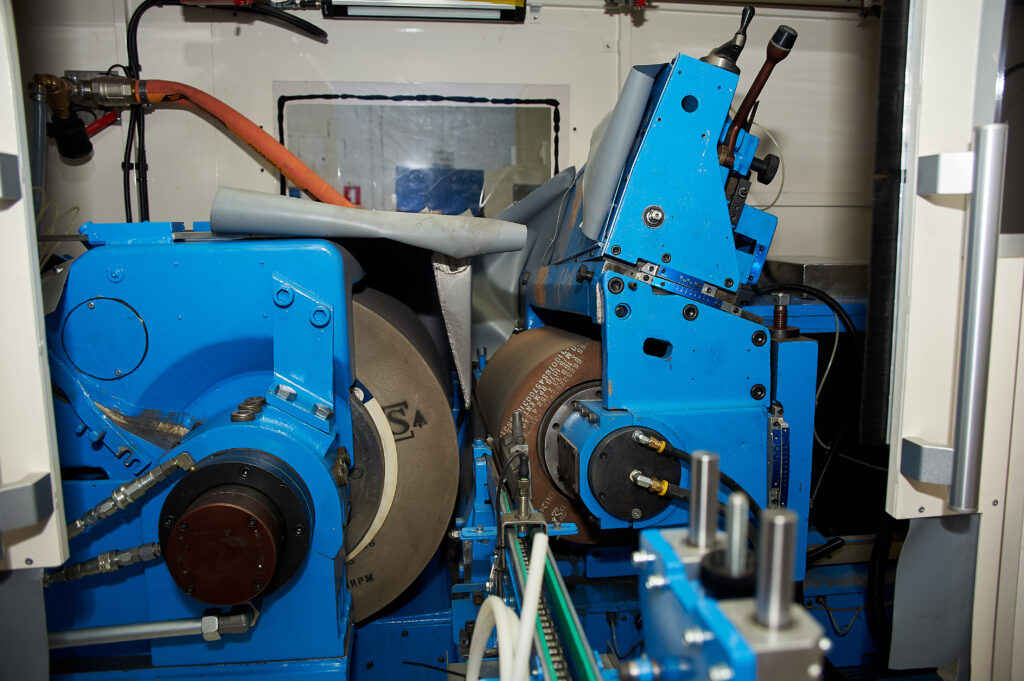

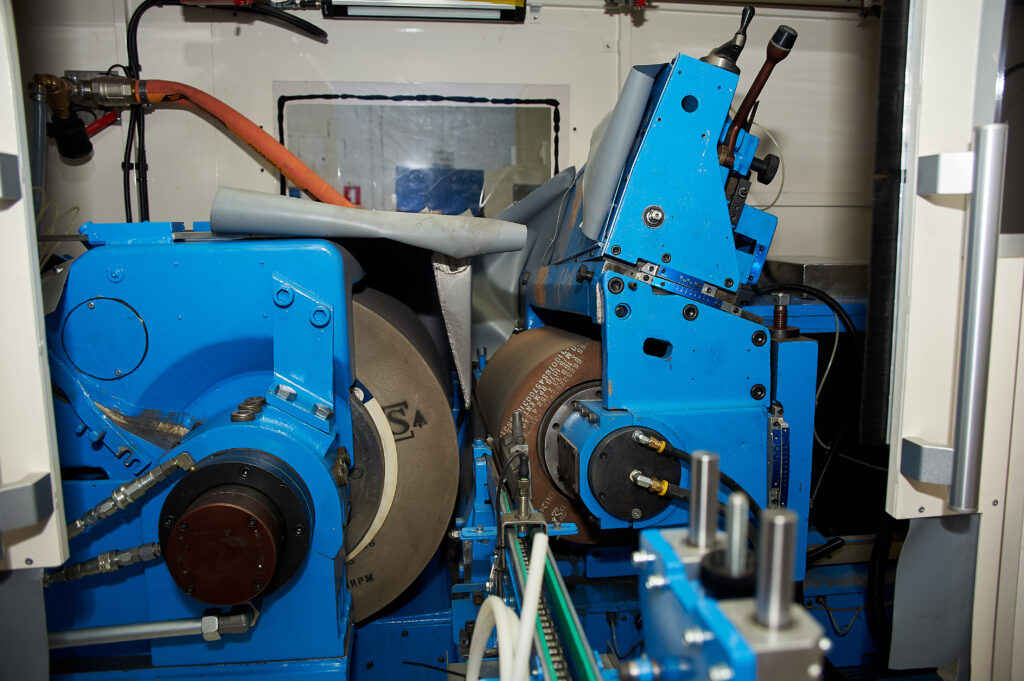

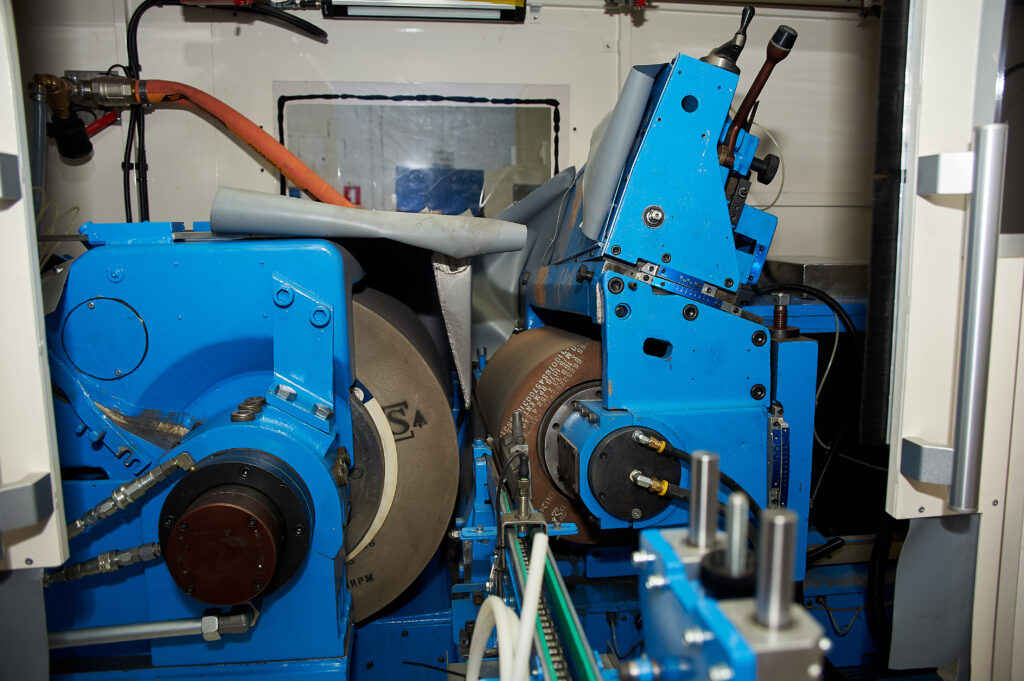

DINATEC is the French manufacturer of new MICROREX centerless grinding machines in the type 0, 1H, 2H, 2L ranges. We have developed a new generation of machines dedicated to the enfilade and plunge processes, with a host of new features.

In fact, these new machines now feature pivoting bases andreinforced guidance for the spindle support bracket and regulating wheel. All types of diamond cutting can be adapted to suit the process required: electrical, digitized, diamond concretion or needles, disc wheel or form wheel. The remote switchgear cabinet offers a wide range of possibilities for installation in your workshops. Our new machines are controlled either by PLC, Siemens or Fanuc, depending on the application.

Our centerless grinders are equipped witha watertight enclosure that can integrate fire protection, connection to a mist filtration system and a misting device. All our machines come with CE conformity and a 12-month warranty.

Our centerless grinding machines are specifically equipped according to your desired configurations in plunge or enfilade mode:

In diving mode only, we can offer the following equipment:

We can offer you periodic preventive maintenance contracts tailored to your needs.

We also provide curative maintenance, taking advantage of our stock of spare parts to get you up and running quickly.

Designed by Krysalidesign